A pre-project feasibility for connecting North- and South-Holland via hyperloop

This review offers an overview of the Cargo-Hyperloop Holland project, part of a broader initiative to create a pan-European, emission-free transport network. The study focuses on the construction of a hyperloop corridor specifically for cargo transport between Amsterdam and Rotterdam, aligning with the Netherlands' interest in sustainable transportation alternatives.

The Hyperloop Development Program, established in 2020, identified the Cargo-Hyperloop Holland corridor as a key component of its vision. This lead to a pre-feasibility study, conducted collaboratively with over 30 private and public entities, investigating the possibility of a hyperloop network within the provinces of North Holland and South Holland. This study thoroughly explored the technical, economic, and logistical aspects of implementing the corridor, including system alignment, infrastructure costs, demand projections, economic performance, risk assessment, and various delivery models.

The Cargo-Hyperloop Holland study represents a step towards envisioning a new mode of transportation that aligns with broader goals of reducing emissions and road congestion. By considering both the opportunities and challenges associated with this emerging technology, the study provides an informed perspective on the potential for hyperloop transport within the context of regional and continental transportation needs.

“We approached this research differently from previously performed hyperloop studies by directly involving the future users of the system as well as other key stakeholders. For this project we established a collaboration of 35 stakeholders from the private and public sectors, including some of the largest Dutch exporters from the horticultural and fresh food industry. They not only provided crucial input to the product requirements but also contributed to selecting the locations of the hubs as well as the route alignment. The project largely follows the A4 motorway, which connects cities such as Amsterdam, The Hague and Rotterdam. The A4 is crucial to the economic performance of this region. However, it also ranks among the most congested in the Netherlands. Currently proposed solutions will only partially solve this issue. Hyperloop could add capacity and therefore ease congestion on existing infrastructure while also increasing connectivity and productivity.” – Dominik Härtl (Global Business Development Manager at Hardt

Urgency

The urgency for executing this project is driven by various environmental and infrastructural challenges. The transportation sector is a significant contributor to CO2 emissions, and there is a global imperative to reduce these emissions. The hyperloop system presents an effective solution to this issue, aligning with the ambitious reduction targets set by the European Green Deal and the Dutch Klimaatakkoord. By opting for the hyperloop system, the project contributes to a more sustainable and eco-friendly transportation network.

Additionally, the regions of North and South Holland face high road congestion, primarily due to cargo traffic. Introducing a hyperloop system offers a swift, efficient, and green alternative to conventional road transport, thus alleviating this problem. The proposed corridor addresses the needs of major European ports and industries, which require better transport solutions to promote economic growth and competitiveness. By providing a dedicated hyperloop corridor for cargo transportation, the project enhances connectivity and facilitates the movement of goods, benefiting both the local and European economies.

Project

The report specifically focuses on the Netherlands' busiest domestic freight corridor, which supports key Dutch export sectors such as horticulture and floriculture, along with associated logistics activities. By integrating producers, traders, buyers, and logistics nodes on this corridor with a hyperloop, the report anticipates a dramatic reduction in the reliance on existing modes of transport, and a significant increase in the speed and reliability of delivery. This implies a marked decrease in maintenance costs for existing infrastructure, thereby mitigating congestion. Moreover, it could lead to substantial improvements in air quality and reductions in CO2 emissions in densely populated areas – a major step towards achieving climate agreement goals.

The Cargo-Hyperloop Holland project focuses on key areas such as sustainability, interconnectivity, and innovation. The main objectives include:

- Alleviating road traffic and congestion on the A4 by introducing an additional mode of transportation.

- Lowering carbon and other transport-related emissions to aid in reaching sustainability goals at regional and national levels.

- Stimulating future economic growth in North and South Holland by enhancing accessibility and connectivity between logistics and industrial centers.

- Kick-starting the development of the European hyperloop network by executing a pilot hyperloop project.

- Enhancing the reliability and reducing transport times for shippers in North and South Holland.

- Yielding savings and increasing the efficiency of other transport infrastructure development initiatives in the region.

The Cargo-Hyperloop Holland project's scope covers the development of a new hyperloop modality to supplement existing transport solutions. This involves the development of linear hyperloop infrastructure, creation of hyperloop hubs for cargo, provision of hyperloop vehicles, and the operation of transport services along the corridor. By doing so, it promises to usher in a new era of fast, efficient, and environmentally-friendly cargo transportation.

Hyperloop System

The hyperloop is an electric transportation system where vehicles travel in a network of low-pressure tubes, reaching speeds up to 700km/h. It uses magnetic forces for levitation and propulsion, reducing air resistance and energy consumption. Notable characteristics of the system comprise its high capacity, impressive transit speeds, energy efficiency, minimal maintenance requirements, absence of operational emissions, compact infrastructure, and cost-effectiveness.

Specifically designed for cargo, the hyperloop addresses the logistics challenge of moving small to medium-sized, standardized shipment units, an area not fully addressed by the transport industry. It is especially beneficial for time-sensitive, demand-sensitive, and high-value products like fresh food, pharmaceuticals, and high-tech equipment. It improves logistics operations' efficiency and cost-effectiveness, enables just-in-time and on-demand deliveries, and allows a seamless transition to digital and automated logistics operations.

The hyperloop also unlocks new market opportunities for such products, reducing market access times, increasing geographical coverage, and enabling new types of services. It also benefits other market segments by optimizing and automating supply chains, extending the coverage of existing logistics facilities, and reducing capital investments in new facilities.

Network

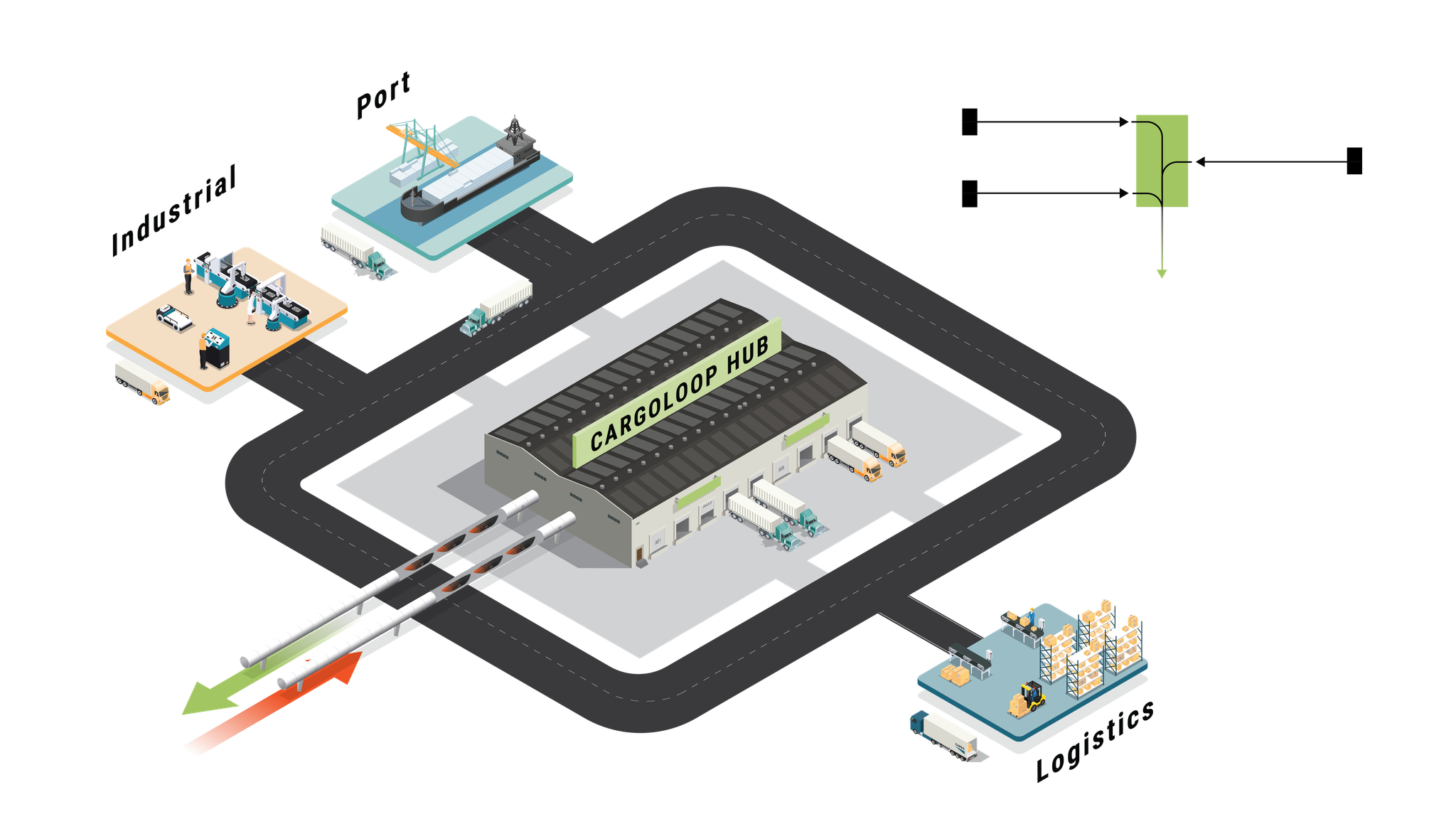

The hyperloop network is an interconnection of various links and nodes. Links, which encompass core, regional, and local categories, facilitate transportation between areas, while nodes, which could be cargo hubs or passenger stations, act as start or end points. Detailed explanations about these links and the different types of cargo hubs will be provided in subsequent sections.

Links

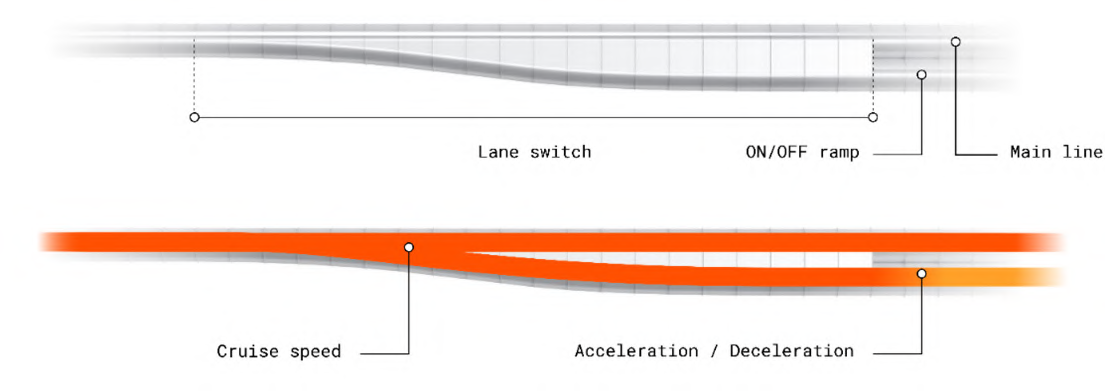

The hyperloop's linear infrastructure includes a network of tubes, expansion joints, and lane switches. The tubes, which are primarily at-grade to minimize environmental impact, are 2.5 m in diameter and can be elevated or placed underground as needed. Expansion joints are used every 60 meters to absorb temperature-induced tube expansion, thereby increasing the operational temperature range.

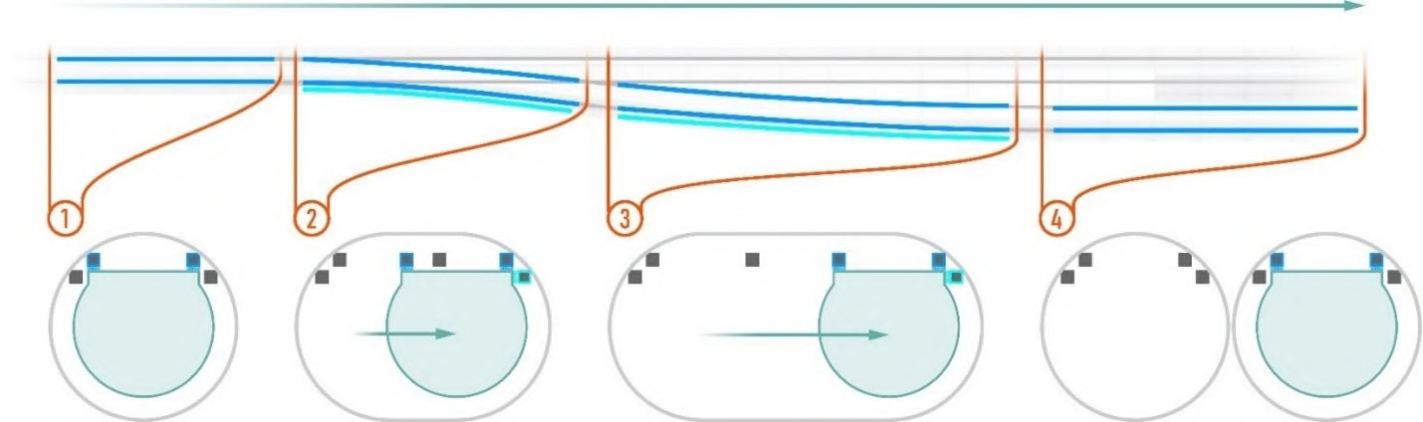

Lane switches are vital in enabling fast-paced intercity travel, allowing pods to change lanes without needing to decelerate. They function through a series of four steps: (1) travel at cruise speed on the main track, (2) subtle reorientation of the vehicle by a guiding magnet, (3) levitation track separation, and finally, (4) entry into a new tunnel. The image below provides a visual representation of this intricate process, which allows for uninterrupted operations. These high-speed magnetic switches are capable of managing multiple vehicles per second, a feat made possible due to the absence of mechanical parts in the infrastructure and the use of electromagnetic forces.

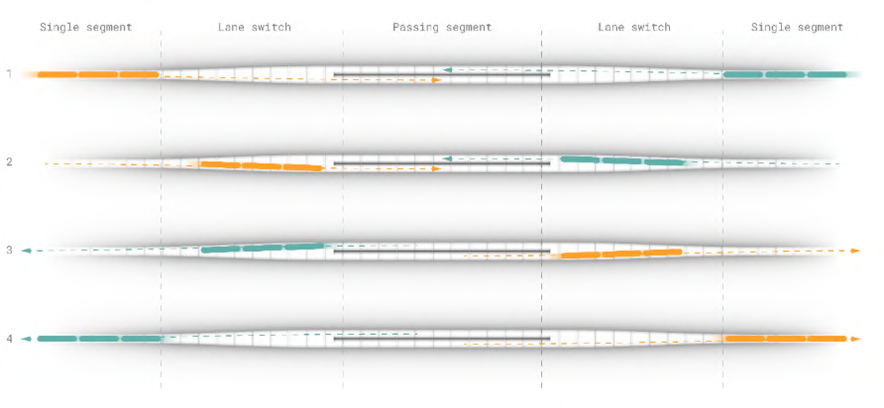

The hyperloop network can utilize single or double tube infrastructure based on anticipated traffic volumes. While double tubes increase capacity by allowing continuous bidirectional vehicle passage, single tubes handle low-traffic volumes by alternating directional flows. On longer routes, single and double tubes are used alternately, allowing vehicles traveling in opposite directions to pass each other. This system's operation is fully automated, enhancing efficiency and throughput.

Hubs

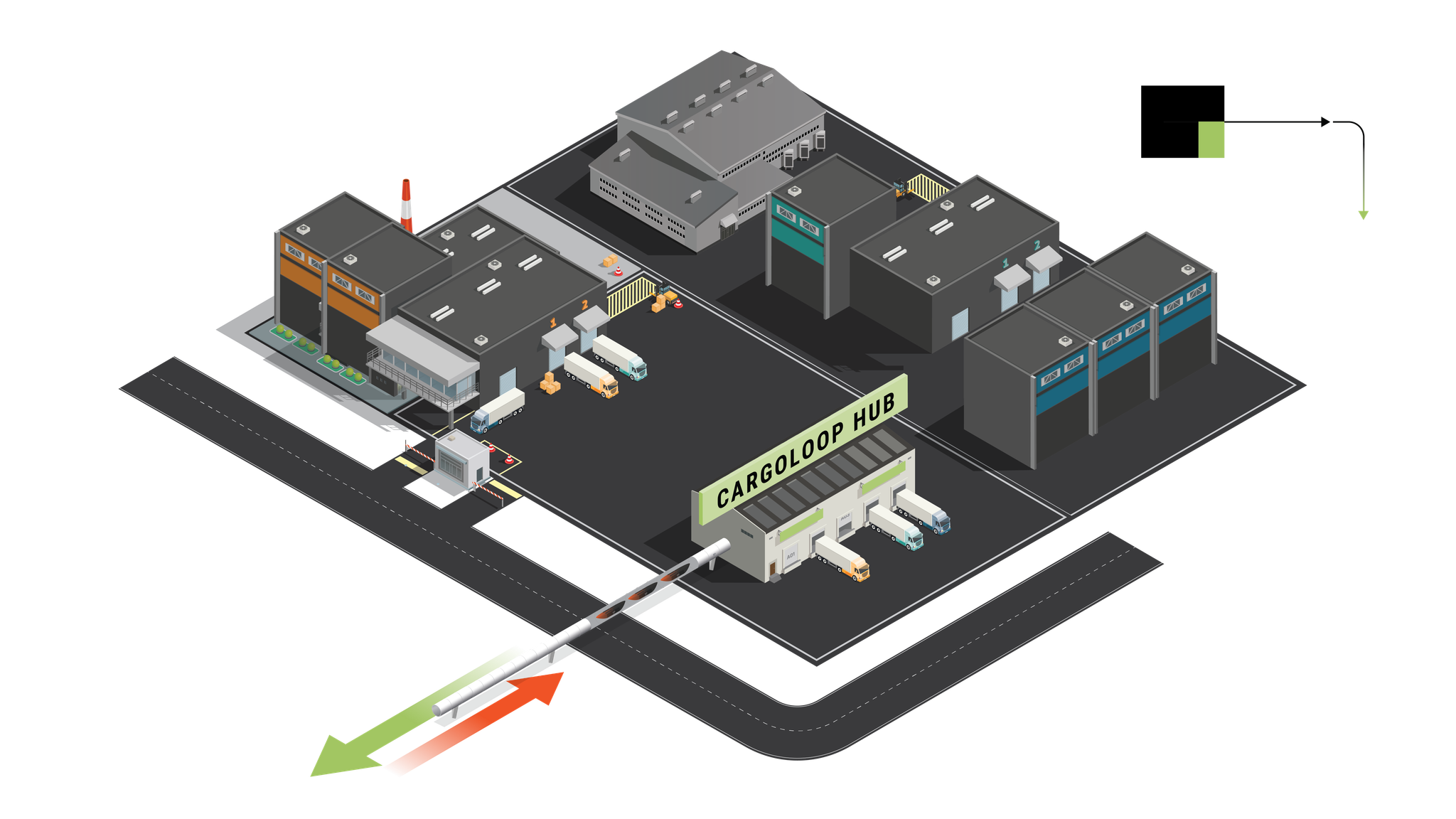

Hyperloop cargo hubs play a vital role in integrating hyperloop technology into existing logistics systems. These hubs are designed to handle various tasks such as loading, unloading, sorting, and staging of cargo. Upon arrival, cargo is efficiently unloaded from trucks using manual or automated methods. It undergoes a meticulous check-in process to verify its details and is then directed to the appropriate area for buffering, sorting, and staging. When the hyperloop route is available, the cargo is quickly loaded onto hyperloop vehicles, taking only a few minutes to complete the process. Upon reaching the destination hub, the cargo is unloaded and sent to the check-out gate for verification. Finally, the cargo is loaded onto trucks from a dedicated staging line for outbound shipping. These hub operations ensure smooth and efficient transportation of cargo using hyperloop technology.

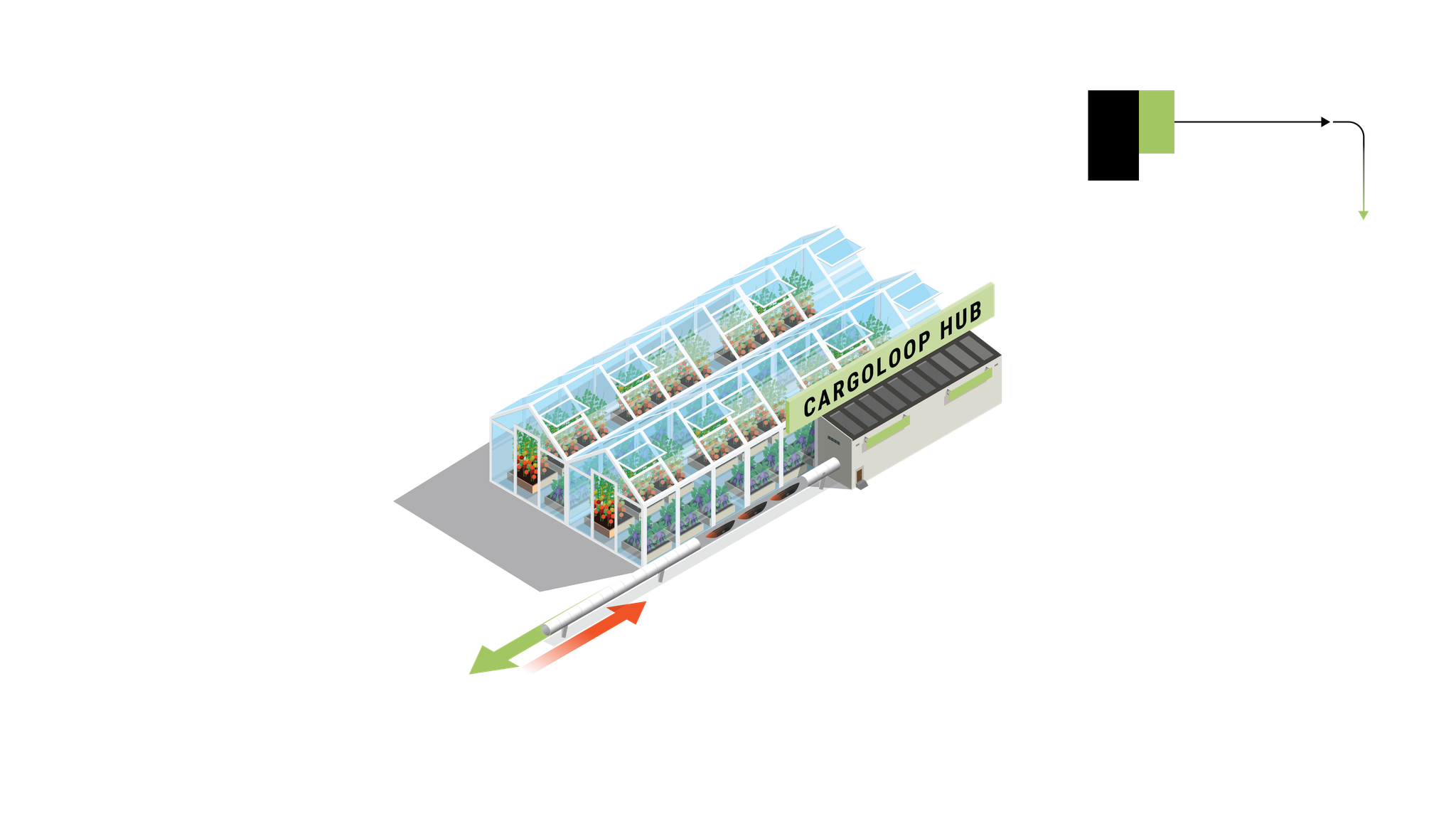

The study references distinct categories of hubs, which are described in more detail below and depicted in the subsequent pictures:

- Regional (or 'Gateway') hubs: These large, high throughput facilities have 4-8 hyperloop loading/unloading platforms and are located within regional business or logistics parks. They have enough space for fundamental hub functionalities and additional activities.

- Local hubs: Medium-sized facilities with 2-4 hyperloop loading/unloading platforms that serve specific business, logistics, or industrial parks. They can establish connections with nearby facilities through automated conveyors while offering sufficient space to fulfill essential hub functionalities.

- Urban hubs: Compact hubs with a single hyperloop loading/unloading platform located on the outskirts of a city or urban area. They focus on emission-free last-mile delivery and have a small physical footprint. Access to urban hubs is limited to lightweight last-mile vehicles exclusively.

- Direct facility hubs: Small facilities with a single hyperloop loading/unloading platform located directly at a cargo-generating facility. They are custom-designed to meet the specific needs of the facility and are not open to third parties.

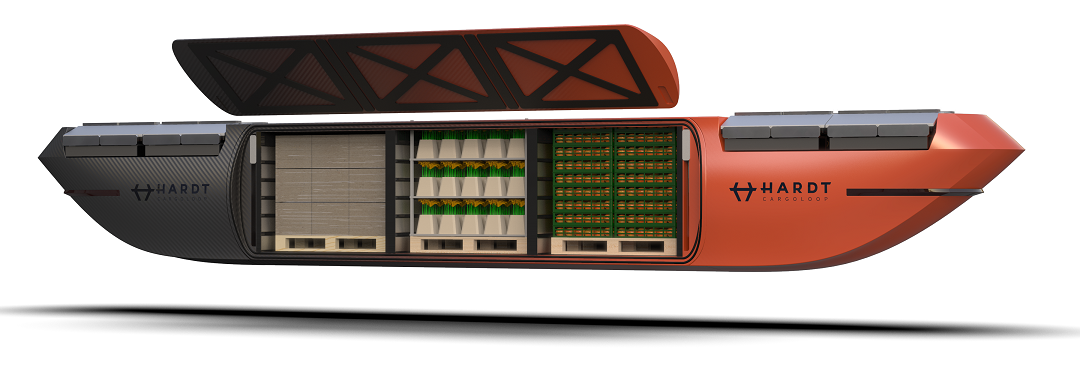

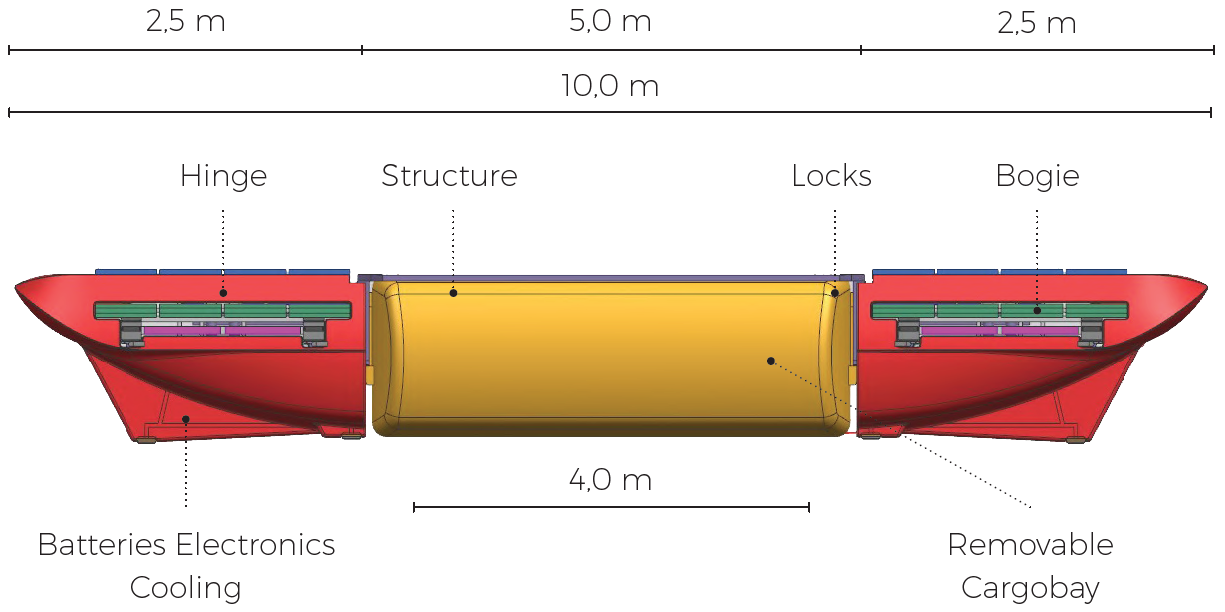

Vehicles

Hyperloop's cargo vehicles are designed to transport small to medium-sized cargo at high speeds while minimizing energy consumption. The vehicles are composed of two nose/tail segments connected by a central structure, all made from lightweight material, reducing both infrastructure costs and energy requirements. The cargo bay, capable of carrying a payload up to 2,500 kg, can accommodate various types of cargo and different pallet configurations. There are considerations to introduce another vehicle type with a smaller cargo bay for more flexible express shipments. To maximize space utilization, the cargo container's height equals its width, accommodating most packaging units with a height limit of 1.20 m.

System Operations

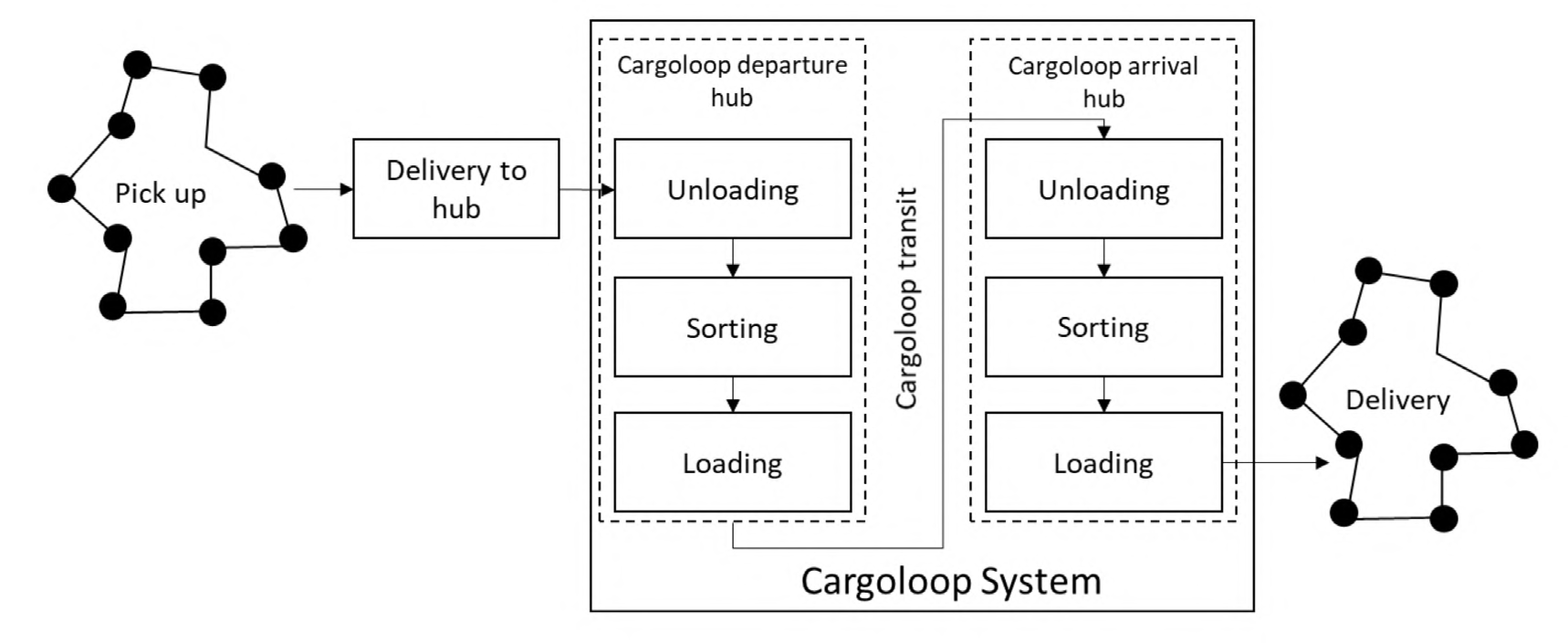

The hyperloop cargo system is integrated within the larger logistics environment, providing a seamless, end-to-end delivery process. It operates in harmony with other transport modes, especially road transport. Cargo is picked up from various locations and brought to the hyperloop departure hub. Here it's unloaded, sorted, and loaded onto hyperloop vehicles for high-speed transportation. Upon reaching the arrival hub, cargo is unloaded, sorted again, and loaded onto trucks for final delivery, as displayed in the figure below.

The hyperloop system offers different service types including express, standard, and overnight services, all designed with specific processing priorities. Express service moves cargo directly from inbound trucks to hyperloop vehicles and vice versa for maximum speed. Standard service holds cargo at hubs, waiting to be grouped with other pallets going to the same destination. Overnight service uses off-peak or overnight delivery windows.

Although the system is expected to operate 24/7, a two-hour maintenance window is assumed, leaving 22 hours for cargo handling operations. Traffic patterns will reflect current road networks, with most cargo handling taking place during working days and peak hours.

To fully utilize the hyperloop system's capabilities, users will need to modify their logistics processes. Shipment dimensions must fit the hyperloop's cargo envelope and additional first and last-mile services may be needed. Companies integrating hyperloop cargo hubs into their existing facilities will need to determine their desired level of automation. Also, utility companies may need to reinforce the electric grid to accommodate the electricity needs of the hyperloop system in high traffic corridors. Emergency response procedures specific to the hyperloop system will also need to be developed.

In terms of power requirements, hyperloop vehicles will be charged at hubs, each requiring a dedicated substation to power the vehicle charging system. The capacity of each substation will correspond with the size of the hub, ranging from 0.25 MVA for one-platform hubs to 2 MVA for eight-platform hubs.

System Costs

The hyperloop system implementation costs include expenditures on infrastructure, vehicles, and additional costs such as planning, procurement, and engineering. The cost of linear hyperloop infrastructure built at grade is estimated at €8.5M per km for a double tube line, including all necessary systems. If built underground, costs can rise by 75-500% depending on the tunneling technology.

The costs of a cargo hyperloop hub with one loading/unloading platform are estimated at €3.7M. A local hub would require €7.3M, while a regional hub would need up to €12.1M for an 8-platform hub. These estimations exclude costs of equipment and space for additional services like sorting and logistics offices.

The cost of each hyperloop cargo vehicle is estimated at €188k. Other costs, such as planning, procurement, and engineering, have been estimated at 6.0% of linear infrastructure capital expenditure. Land acquisition costs have not been included in these estimations as it is assumed that the limited space needed for the hyperloop infrastructure can be provided by the public sector free of charge.

Operational and maintenance costs of the hyperloop system consist of several components, including selling, general, and administrative expenses, energy costs, vehicle maintenance costs, asset insurance costs, and infrastructure maintenance costs. Except for energy consumption costs, all costs have been estimated based on a review of international literature on other modes of transportation. The energy consumption costs are based on the vehicle concept developed by Hardt.

Corridor Alignment

Hubs

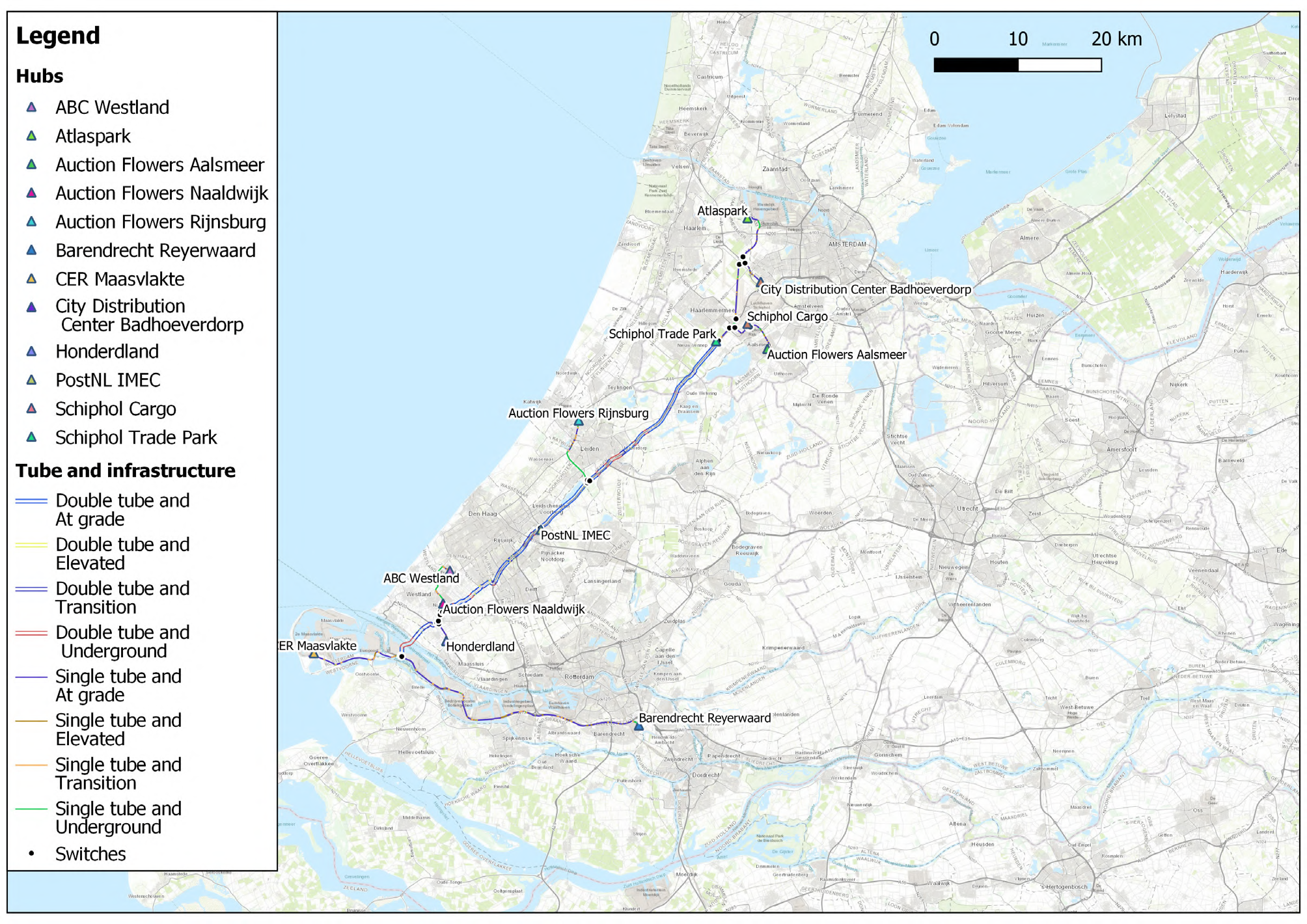

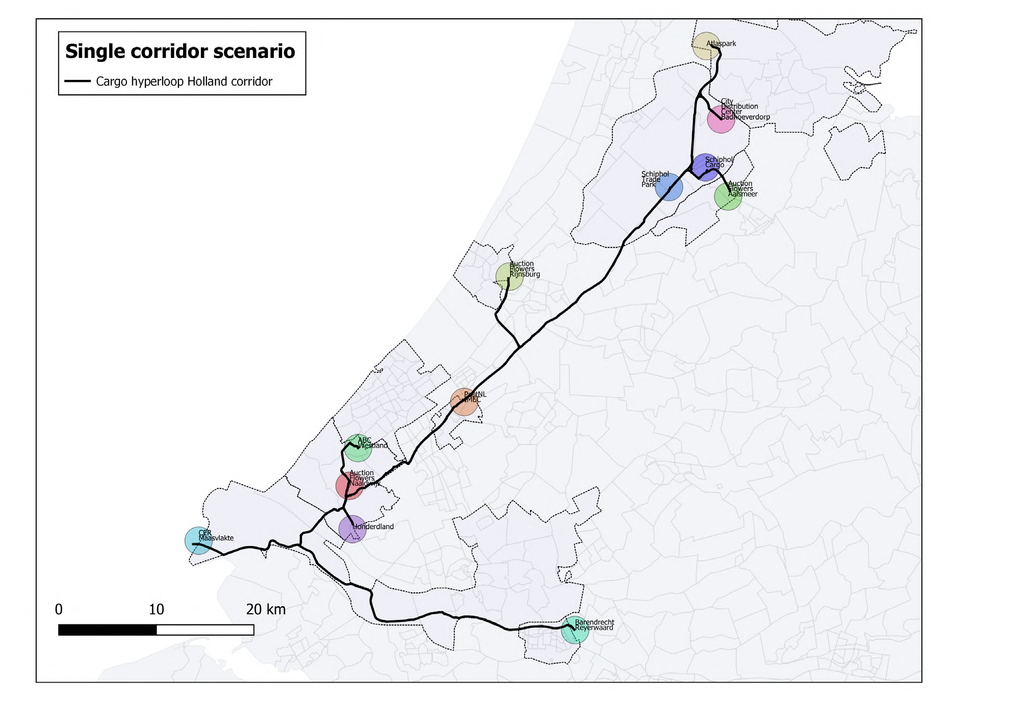

Hyperloop hubs are integral in the hyperloop system, functioning as key gateways for cargo intake and discharge while also interfacing seamlessly with other forms of transportation. As shown in the table below, twelve hubs have been strategically positioned along the Cargo-hyperloop Holland corridor, a placement made possible through collaborations with a broad spectrum of stakeholders. These hubs connect major logistics locations and provide access to production and distribution facilities for key goods produced in the area. Out of these, five hubs are designated as regional, offering services to larger areas, while the remaining seven are local hubs, focusing on servicing specific logistics facilities.

Cargo hyperloop hub | Municipality | Hub function | Major product types |

ABC Westland | Westand | Local | Best fit - Time sensitive goods |

Atlaspark | Amsterdam | Local | Other - Products that are physically suitable |

Auction Flowers Aalsmeer | Aalsmeer | Regional | Best fit - Time sensitive goods |

Auction Flowers Naaldwijk | Westland | Local | Best fit - Time sensitive goods |

Auction Flowers Rijnsburg | Katwijk | Regional | Best fit - Time sensitive goods |

Barendrecht Reyerwaard | Barendrecht | Regional | Best fit - Time sensitive goods |

City distribution center Badhoeverdorp | Amsterdam | Local | Other - Products that are physically suitable |

Honderdland | Westland | Local | Best fit - Time sensitive goods |

CER Maasvlakte | Rotterdam | Regional | Other - Products that are physically suitable |

PostNL IMEC | The Hague | Regional | Other - Products that are physically suitable |

Schiphol Cargo | Haarlemmermeer | Local | Other - Products that are physically suitable |

Schiphol Trade Park | Haarlemmermeer | Local | Other - Products that are physically suitable |

Half of the hubs will primarily handle time-sensitive products, including horticultural and fresh food products. It is assumed each hub will have a power substation for charging hyperloop vehicles. The total capacity required to power the Cargo-Hyperloop Holland corridor is estimated to be about 17 MVA. By contrast, a similar-length rail corridor in the Netherlands requires about ten times more power, around 175 MVA, and a 150 km long high-speed rail corridor requires 480 – 540 MVA.

Linear Infrastructure

The design and alignment of the Cargo-Hyperloop Holland corridor are primarily dictated by certain assumptions derived from the hyperloop's technical concepts. Predominantly, the hyperloop infrastructure is envisioned to be constructed along existing highways, railroads, bridges, and tunnels, making efficient use of available public spaces. The layout of the hyperloop consists of both single and double tube segments, depending on the expected traffic volumes, as shown in the figure below.

Based on these technological concept assumptions, the corridor is designed to be 149 km long, featuring 26 switches at hubs located at various junctions. Primarily, the corridor is planned at ground level, constituting 67% of its design. The remaining portions are distributed between elevated (5%), underground (21%), and transitional (7%) segments. The majority of the corridor will comprise a single tube line (64%), while a double tube configuration is planned for the remaining 36%.

To ensure harmony with existing infrastructure, protected areas, and planned developments, the alignment of the corridor underwent thorough evaluation to mitigate potential conflicts. Notably, major risks surfaced concerning the future widening of the A4 highway and the addition of a runway at Schiphol airport. By adjusting the alignment, the conflict with the A4 widening was successfully addressed, while the proposed runway addition necessitates further discussions with Schiphol Airport and the government.

The alignment accommodates high speeds, allowing up to 400 km/h on almost half of the route, with the remaining sections limited due to spatial integration requirements. Thus, the design strategy, anchored in the technological concept assumptions, optimizes the use of space while enabling efficient, high-speed transport.

Demand Assessment

Scenarios and Goods

The Cargo-Hyperloop Holland demand projections in this study have been developed under four distinct scenarios:

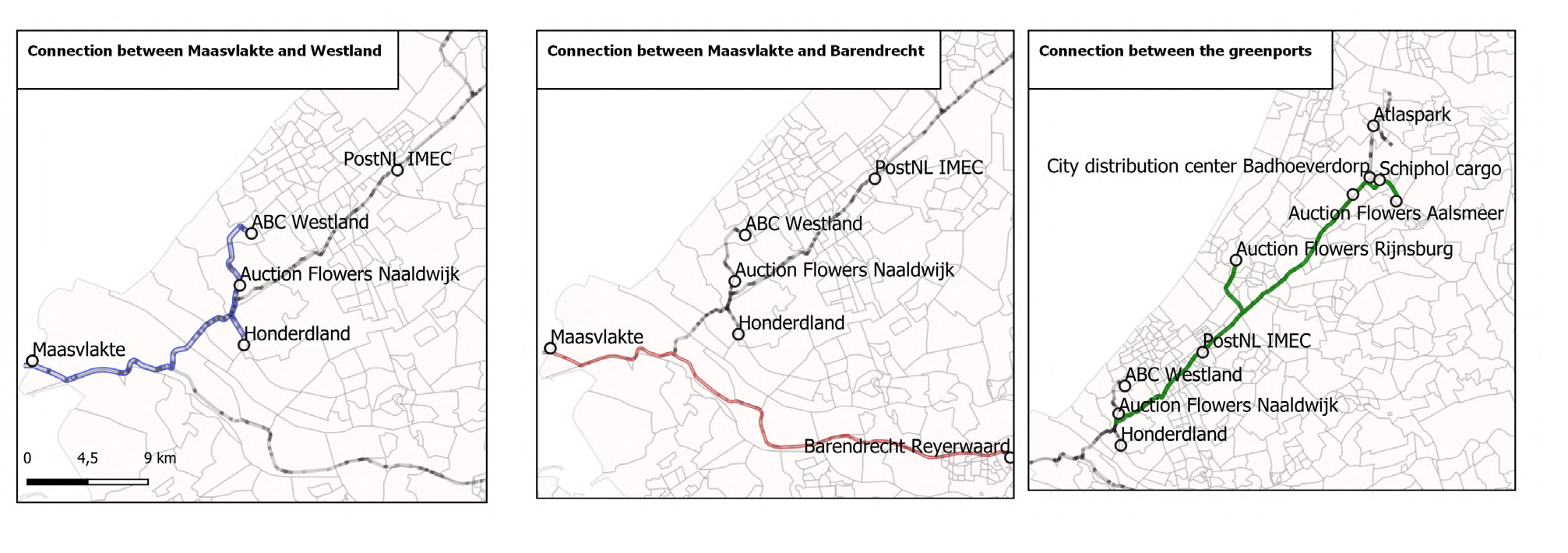

- Single section scenario: Each of the three sections of the Cargo-Hyperloop corridor is evaluated as separate entities, assuming their standalone operation starting in 2029.

- Single corridor scenario: The entire Cargo-Hyperloop Holland corridor is evaluated as a whole, assuming its full operational status in 2029.

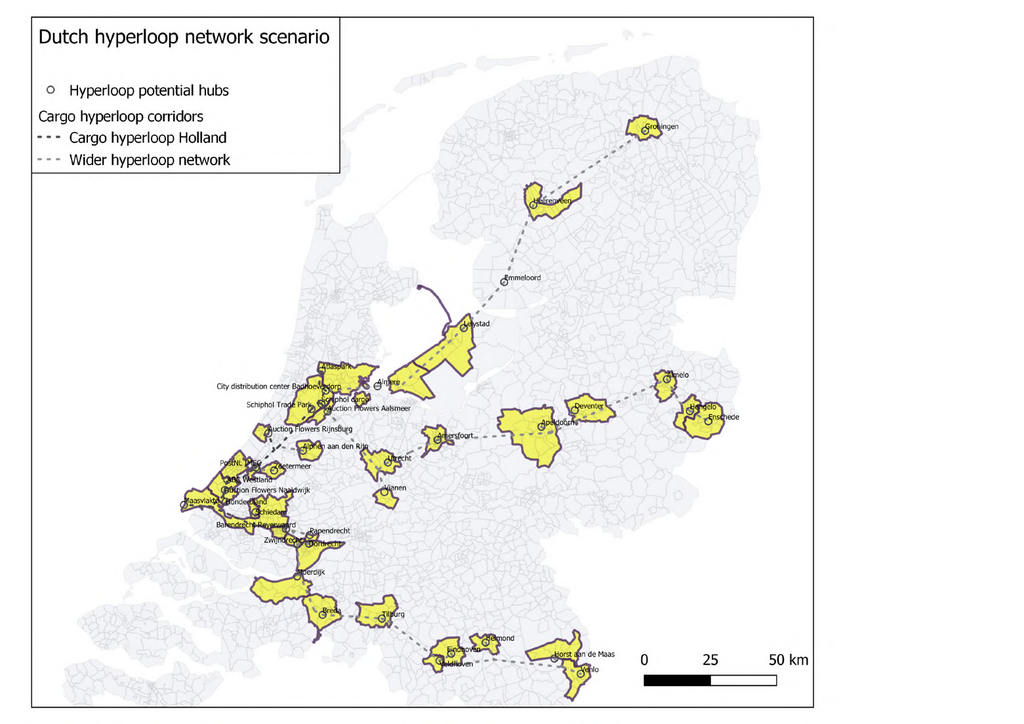

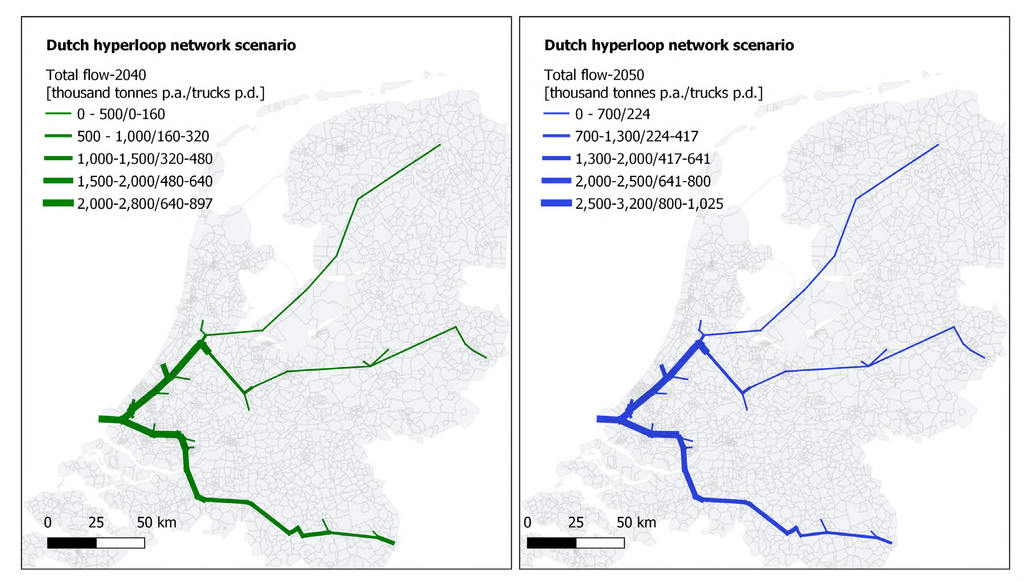

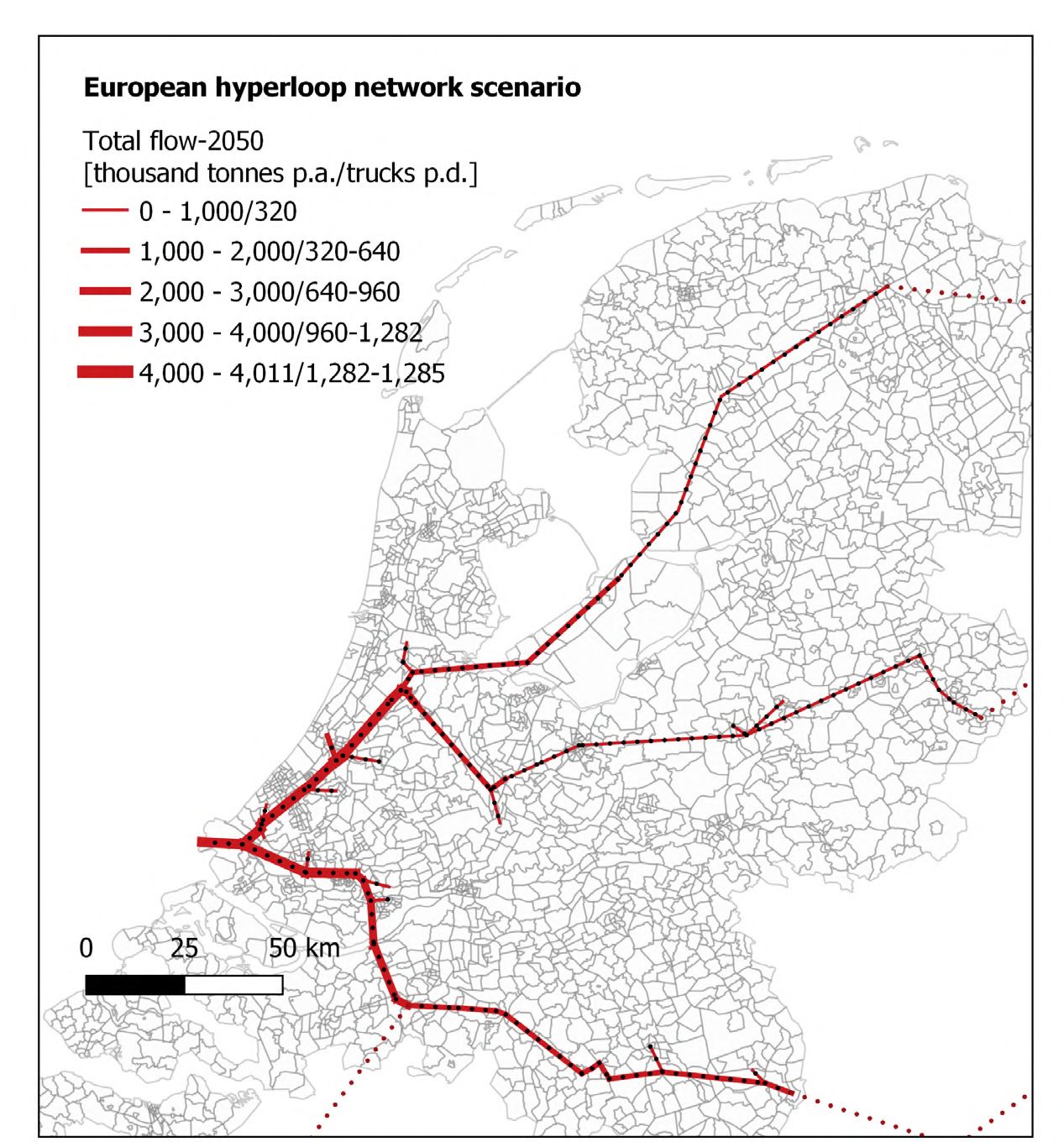

- Dutch hyperloop network scenario: The Cargo-Hyperloop Holland corridor is considered as part of a future Dutch hyperloop network, allowing for increased connectivity and the effects of an expanded network.

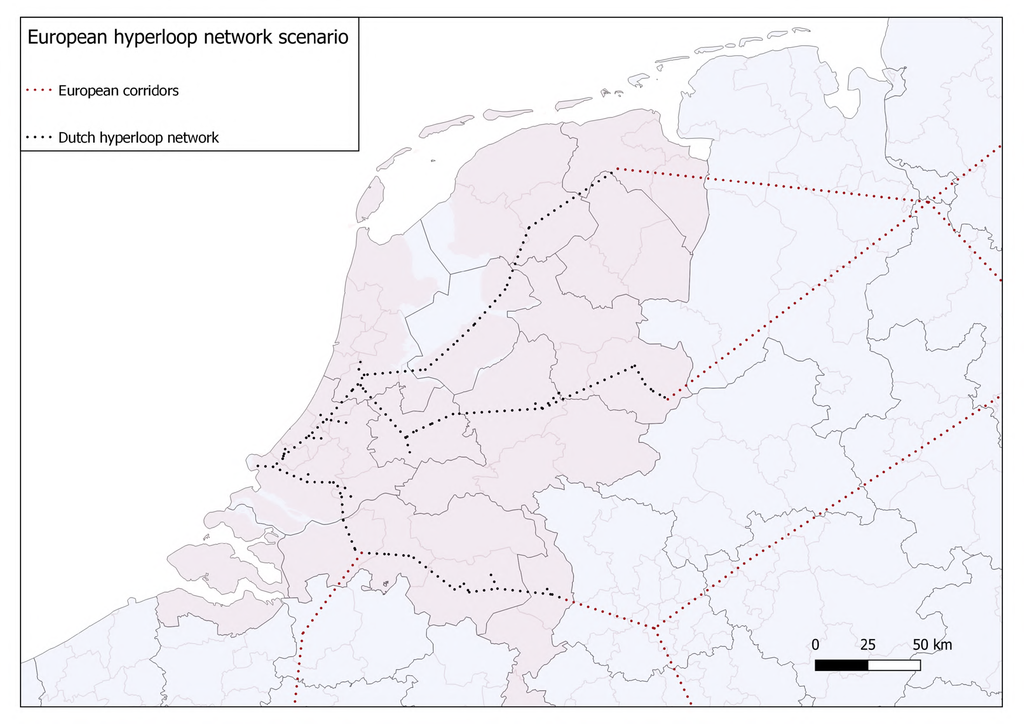

- European hyperloop network scenario: The corridor is evaluated as part of a potential European hyperloop network, considering the network effect from increased connectivity across Europe by 2050.

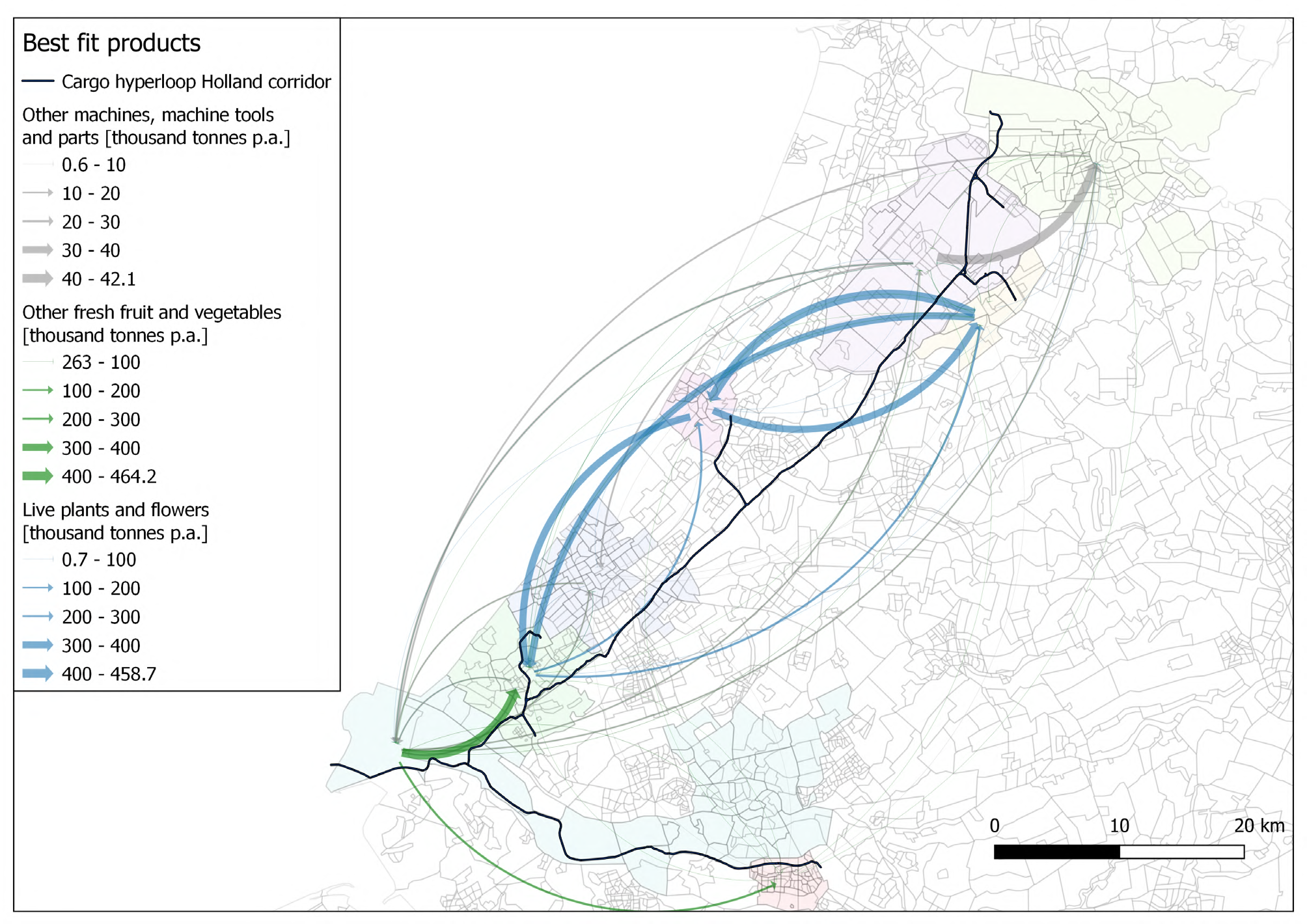

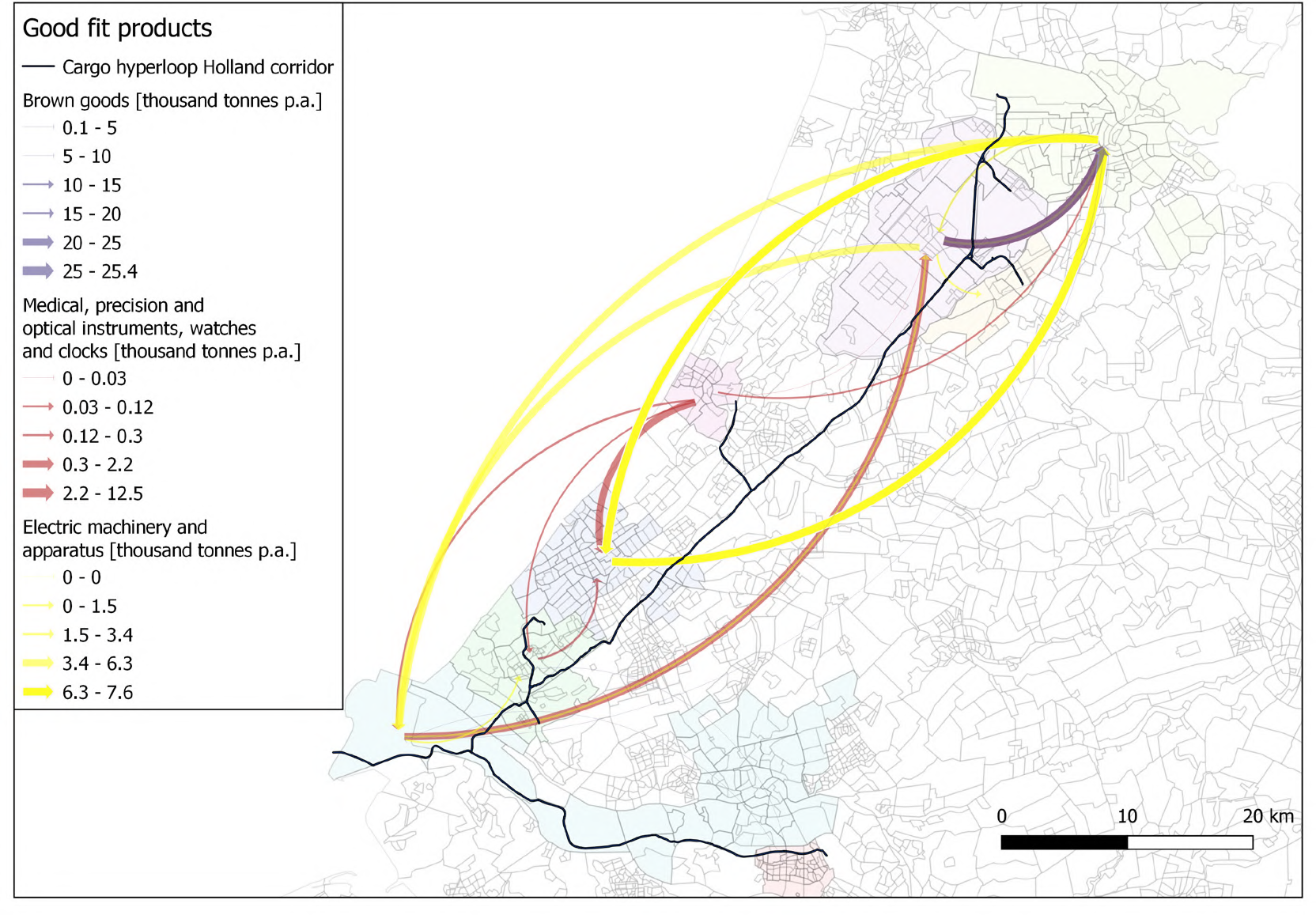

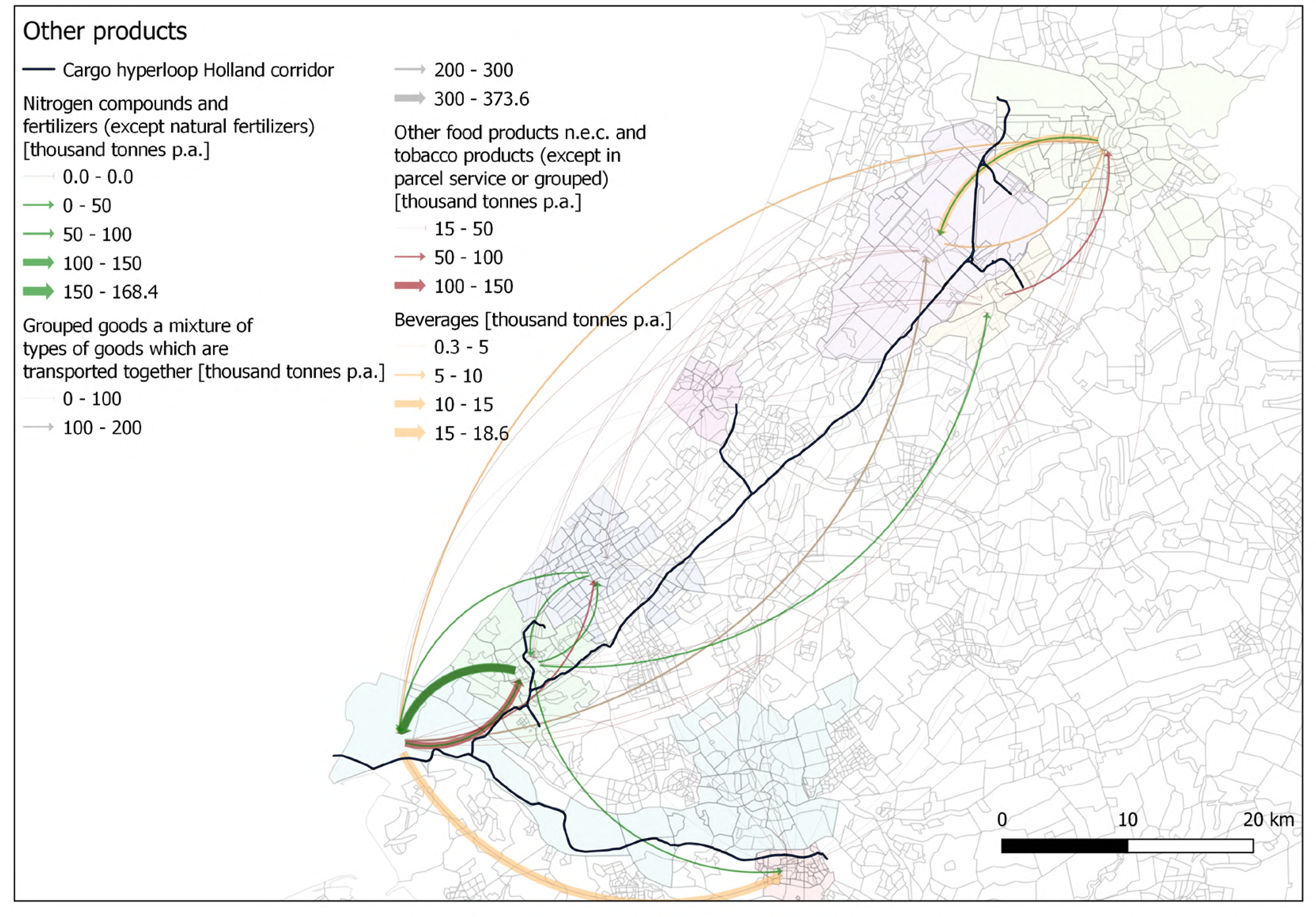

Regarding cargo, the hyperloop targets primarily time-sensitive, high-demand, and high-value goods such as fresh food, pharmaceuticals, e-commerce products, fashion, electronics, and high-tech equipment. These products are divided into three categories for demand assessment:

- Best-fit products: Time-sensitive goods that would greatly benefit from hyperloop's expedited transportation, such as fresh perishable produce, pharmaceuticals, spare parts for various industries, and e-commerce products.

- Good-fit products: High-value goods that could benefit from reduced transit times, while absorbing some transportation cost increases. These include electronics, high-end clothing, and jewelry.

- Other products: Products that are physically suitable for Hyperloop transportation and could gain market advantage or financial savings. These include processed food, bottled beverages, tobacco products, and chemicals.

Different demand volumes and modal shift assumptions are made for each product category in the future.

Current cargo flows

The demand assessment for the Cargo-Hyperloop Holland corridor was comprehensively conducted using a combination of different data sources and analytical methods. CBS data and a separate dataset were utilized to comprehend cargo flows, encompassing all cargo types excluding horticultural products, which used a distinct dataset.

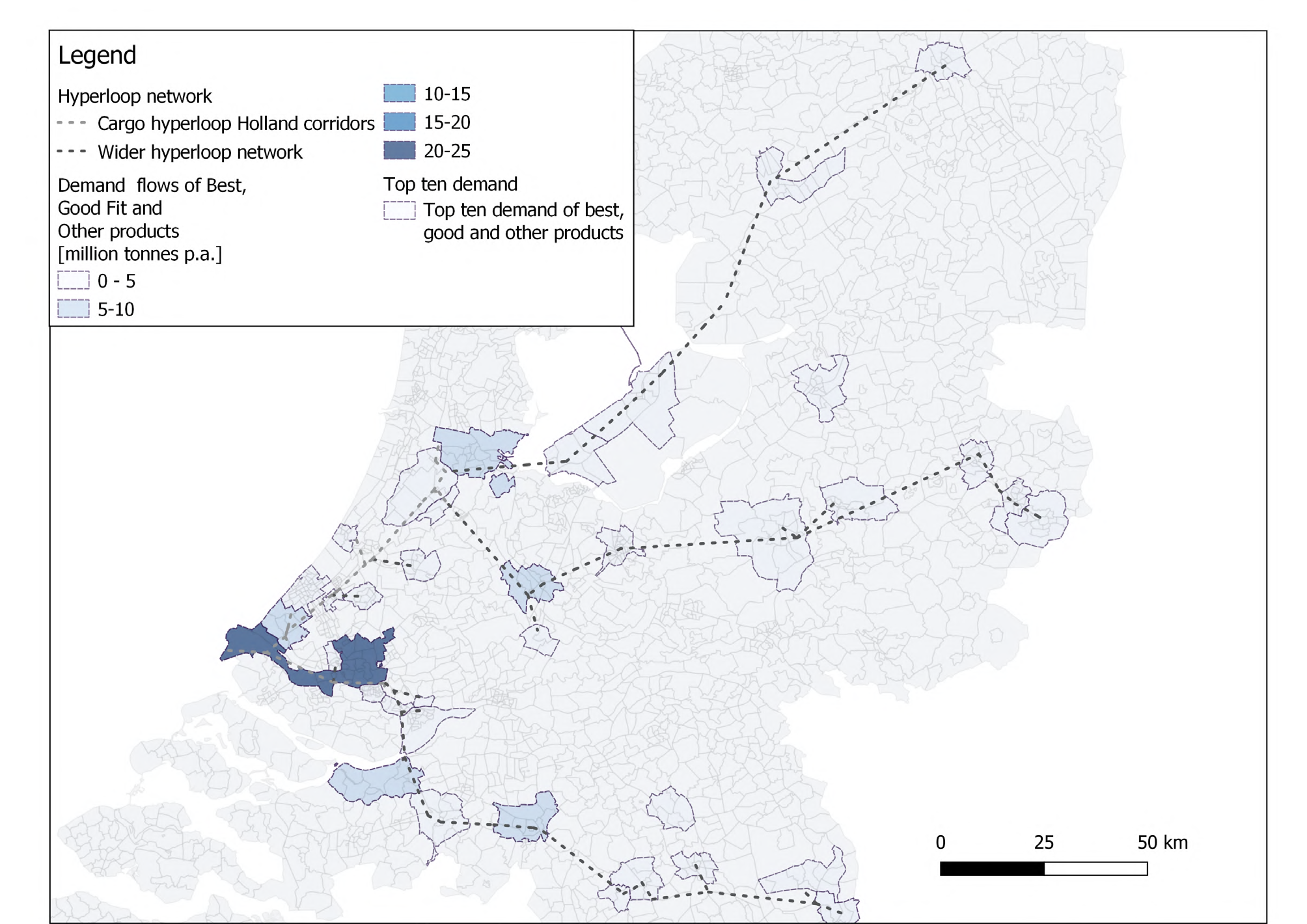

Three different perspectives were employed to analyze the current cargo flow volumes and patterns: the origin-destination analysis, area-based analysis, and modal analysis. This multilayered approach allowed for a more nuanced understanding of the cargo flows. From these analyses, it was determined that the total cargo flows along the Cargo-Hyperloop Holland corridor amount to 6.5 million tonnes per year.

The major cargo flows in the corridor include live plants and flowers, fresh fruits and vegetables, and machines, machine tools, and parts. A network of interconnected hubs emerged from these cargo flows, mainly between Amsterdam, Westland, Aalsmeer, Katwijk, Rotterdam, and Barendrecht.

In order to gauge the wider implications of the corridor implementation, an analysis of the current cargo flows between the future Cargohyperloop Holland hubs and the rest of the Netherlands and Europe was conducted. This examination showed that the total cargo flows between the future hub locations and the rest of the Netherlands reached up to 25.4 million tonnes in 2018. This presents a significant potential demand for the Cargohyperloop Holland corridor if the Dutch and European hyperloop network is widened.

In the context of road traffic, the cargo flow analysis for the Cargohyperloop Holland corridor was based, and an average truck load of 12 tonnes was assumed. This feeds into a more comprehensive understanding of the overall cargo flows and sets the stage for the detailed demand assessment to follow in the subsequent sections.

Projection and Distribution of Demand

Demand projections for the Cargo-hyperloop Holland corridor have been prepared for the period of 2029 – 2058, covering 30 years since the corridor's first operational year. These projections were made considering 2029 as a transition period when the market adapts to hyperloop as a new transportation mode.

The growth rates used for these forecasts stem from the WLO scenarios for overland freight transport, created by the Dutch Central Planning Office. The WLO, a Dutch investigation presenting future demographic, economic, and environmental scenarios, guides policy-making decisions. Two scenarios were offered – a high scenario that anticipates annual growth rates of 1.1% - 1.3%, and a low scenario that assumes growth rates of 0.2% - 0.4%. These growth rates were then applied to project the volumes for 2030, 2040, and 2050 from current volumes.

Considering the current 5% annual growth trend in truck transportation in the Zuid-Holland region, the high WLO scenario was used as a benchmark for the demand forecasts.

The projected demand for the hyperloop system is expected to instigate a shift in cargo traffic from other forms of transportation, mainly roads, to the hyperloop. This shift, however, will necessitate prospective users to adjust their logistic processes.

The demand distribution analysis performed under the four scenarios provided the following results:

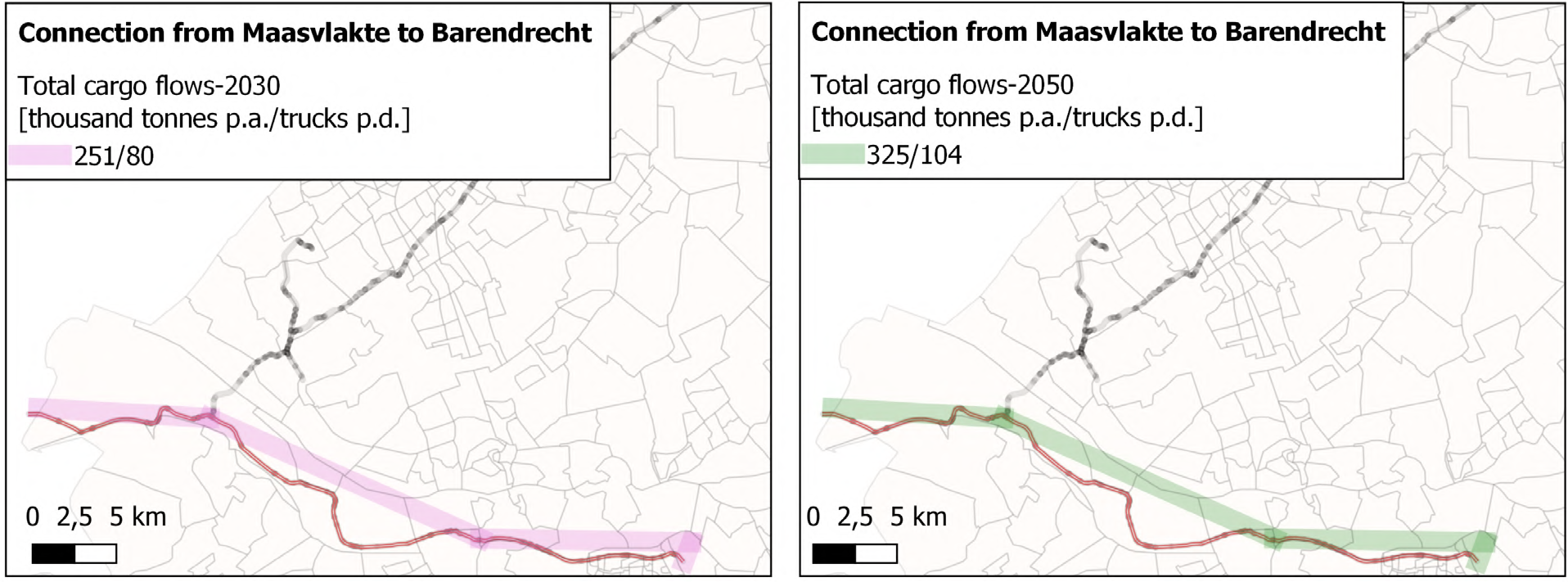

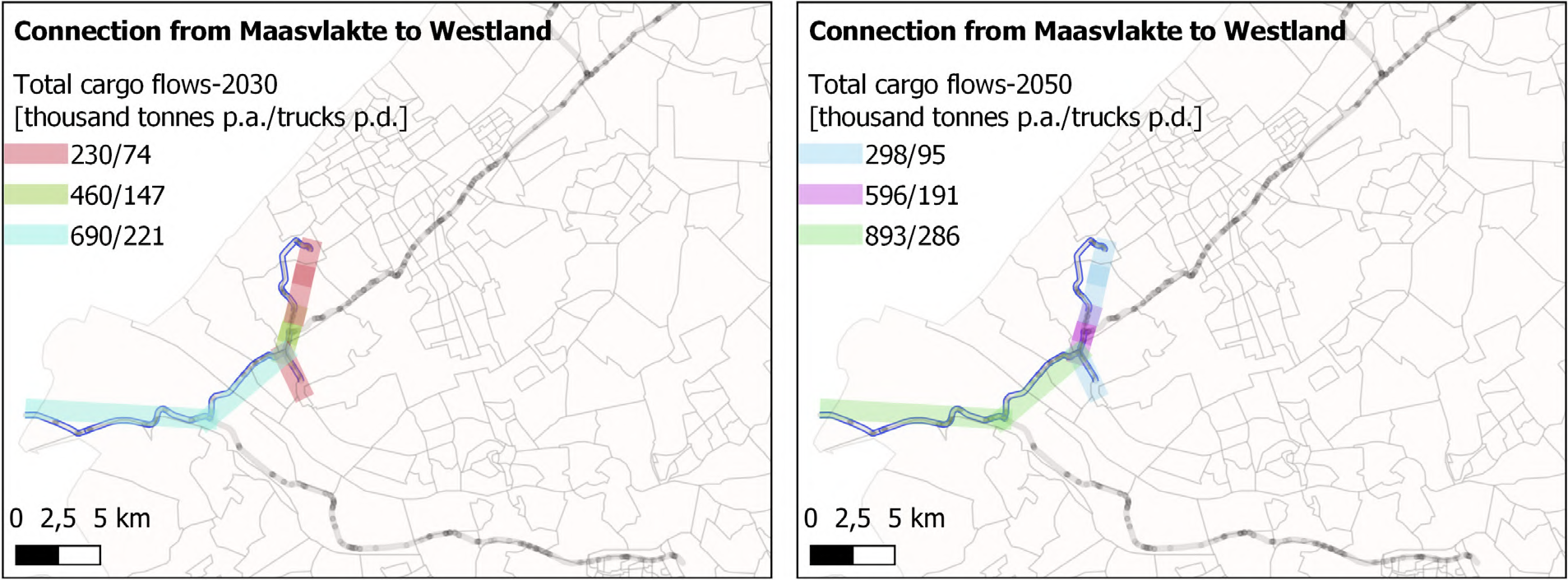

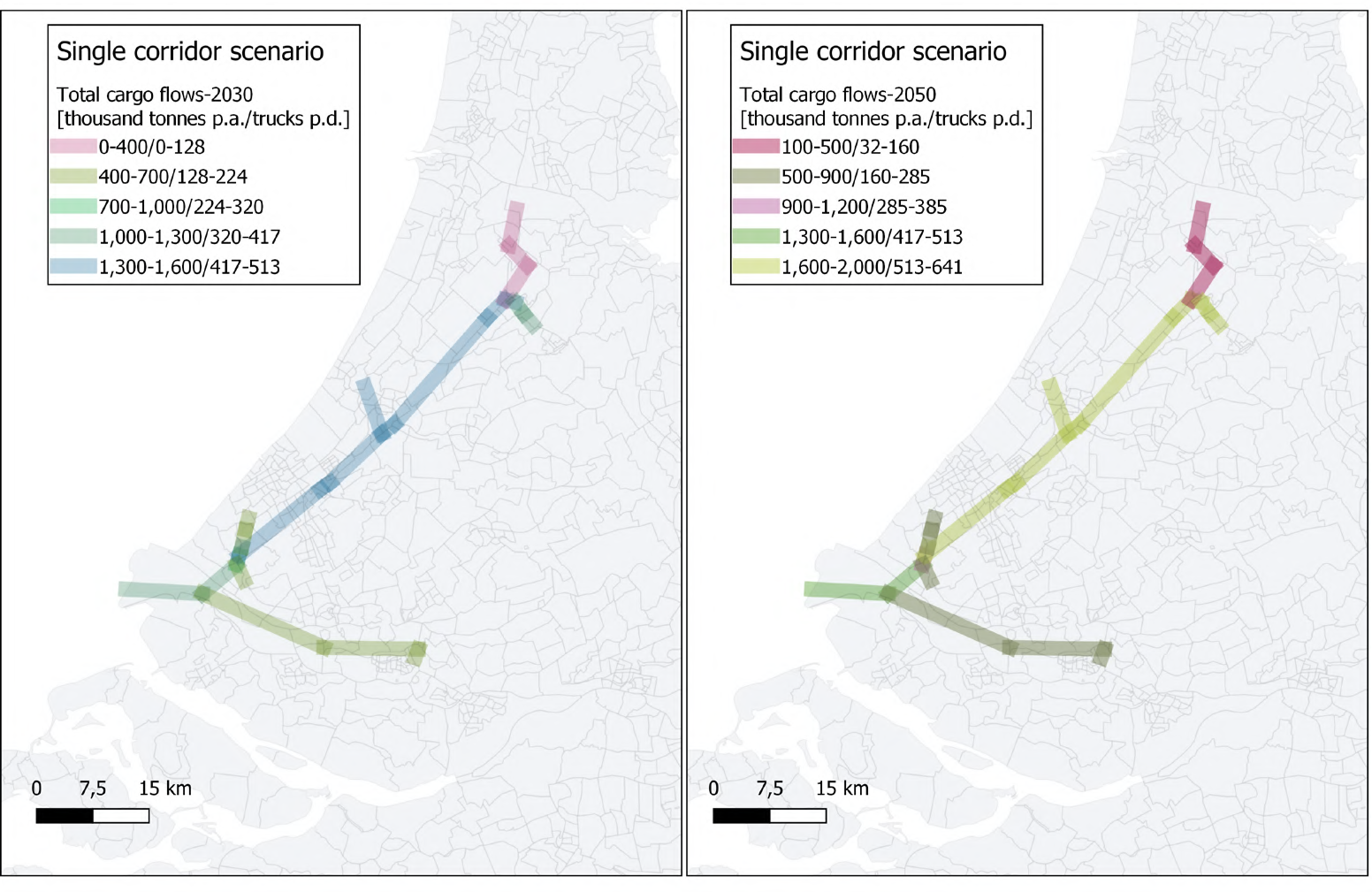

- Single section scenario: Analyzing each corridor section separately shows that by 2050:

- Maasvlakte - Barendrecht could transport 0.33 million tonnes annually via hyperloop, removing 104 trucks per day from the road.

- Maasvlakte - Westland could transport 0.9 million tonnes annually via hyperloop, removing 286 trucks per day from the road.

- Naaldwijk - Rijnsburg - Aalsmeer - Amsterdam Schiphol Airport could transport 2.0 million tonnes annually via hyperloop, removing 660 trucks per day from the road.

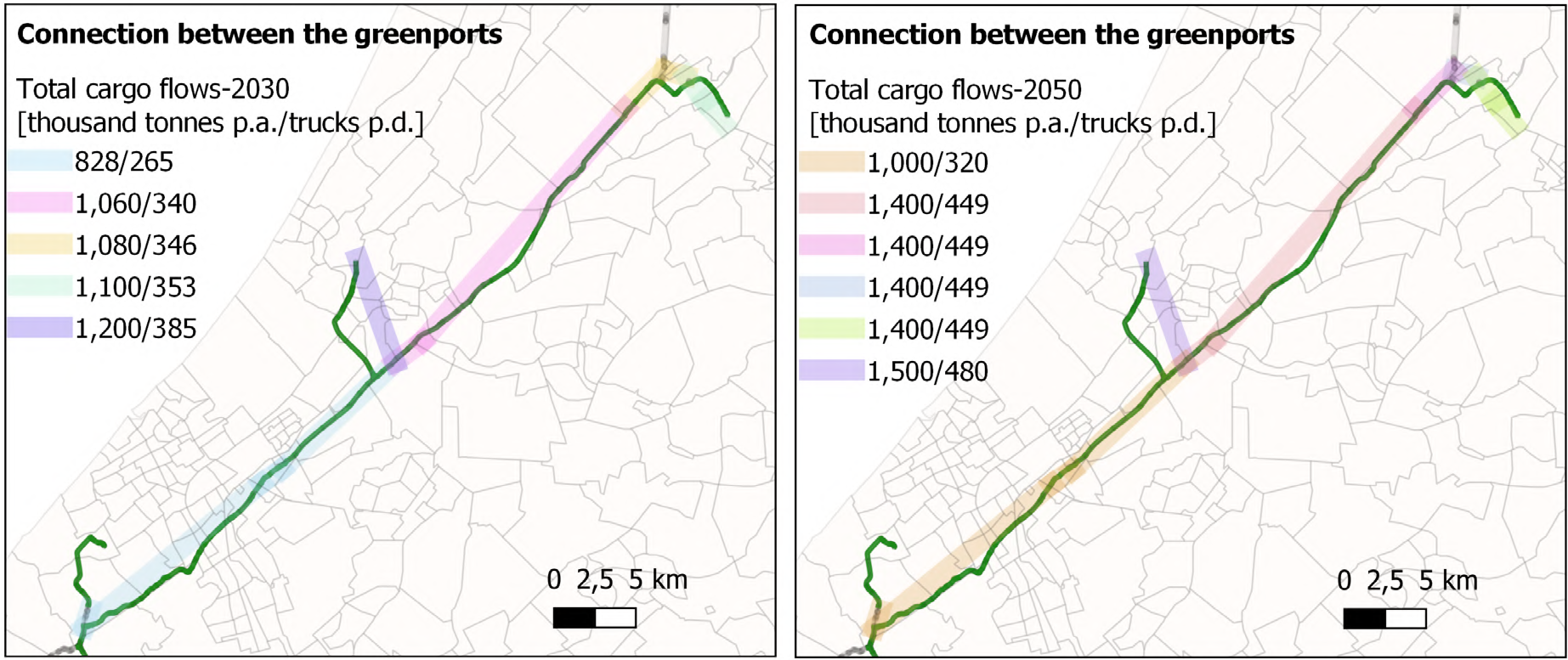

- Single corridor scenario: Evaluating the corridor as a whole projects hyperloop transport of 3.4 million tonnes of cargo in 2030 and 4.4 million in 2050, equating to a reduction of 1,412 trucks per day on the roads.

- Dutch hyperloop network scenario: Considering the corridor as part of the future Dutch hyperloop network anticipates transport of 6.3 million tonnes of cargo in 2050, reducing the number of trucks by 5,075 per day on the roads, with a CAGR of 5.93% from 2030 to 2040.

- European hyperloop network scenario: Envisioning the corridor as part of a future European hyperloop network expects transport of 7.9 million tonnes of cargo in 2050, equating to a reduction of 2,517 trucks per day on the roads, with a CAGR of 3.50% from 2040 to 2050.

In conclusion, the Cargo-Hyperloop Holland corridor, once operational, will offer a sustainable and efficient transportation option to the logistics sector. Its effectiveness is reliant on the growth of the hyperloop network connecting logistical hubs across the Netherlands and Europe. Upon completion in 2030, it's anticipated to transport 3.4 million tonnes of cargo, rising to 5.6 million tonnes by 2040 with the completion of the Dutch hyperloop network, and eventually reaching 7.9 million tonnes by 2050 as the European network expands. Besides facilitating cargo transport, this corridor will alleviate congestion on Dutch roads, starting with the removal of 1,091 daily truck journeys from the A4 motorway between Rotterdam and Amsterdam in 2030, and potentially reducing truck traffic by 2,517 daily journeys by 2050.

Economic Assessment

The economic assessment of the Cargo-Hyperloop Holland corridor involves a 30-year social cost-benefit analysis (CBA), aligned with EU practices for transport projects. The analysis considers various impacts, such as financial effects, carbon emissions, external effects like noise and pollution, and employment. In line with the previous section, different scenarios like single section, single corridor, Dutch hyperloop network, and European hyperloop network are analyzed.

Impact Assessment

Financial Impacts

The financial evaluation implements constant 2021 prices and omits factors like inflation, profit tax, and financing costs such as interest payments. Development and capital expenditures are calculated using a standardized methodology, excluding costs for elements like land purchase and visual pollution. The total cost for the entire corridor infrastructure stands at €1473M.

Operational requirements are determined using specific parameters like daily operating time and average speed. These parameters were used to estimate the required number of vehicles, projected to exceed 600 long-term, with an associated cost of approximately €121.4M. The hyperloop operation is projected to be highly cost-effective, with the total operational expenditures for the EU network scenario estimated at €393.5M.

Revenue prediction utilizes demand figures, growth rates, and a freight rate of €0.25/t/km. The EU network scenario's total revenue over the project's lifespan is projected at €2,242M. Other scenarios such as Maasvlakte - Westland, Maasvlakte - Barendrecht, Greenports, Corridor only, and corridor with NL network are projected to generate revenues of €171.5M, €95.4M, €602.2M, €1,471.1M, and €1,979.4M respectively.

Impact of CO2 Emissions

The carbon emission analysis encompasses both the production and construction of the hyperloop infrastructure as well as its operational phase. During the construction phase, the CO2 emissions for the single-tube hyperloop infrastructure range between 400 to 2,700 tons per kilometer. The hyperloop system's operational phase also contributes to CO2 emissions, primarily driven by energy consumption approximated at 15 Wh/tonne-km.

The analysis factors in the anticipated improvement in energy production over time, aligning with decarbonization needs and technological progress. Transitioning freight transport to the hyperloop system could potentially reduce CO2 emissions, though the improvement rate within the trucking industry remains uncertain. The economic value of CO2 emissions was determined using the Netherlands' CO2 pricing, with projections suggesting an escalating CO2 price over time, leading to a positive economic impact due to emission savings.

Conclusively, the project shows promising potential to enhance sustainability and decrease CO2 emissions in the transportation industry.

Impact on Shipping Industry and Users

The hyperloop offers significant advantages to the shipping industry and users, such as reduced delivery times and enhanced reliability. These benefits vary according to product characteristics, resulting in diverse benefits for different goods. Over the long term, the corridor is projected to generate over €2B in economic benefits for users.

External Impact

The project's external impact assessment encompasses benefits stemming from reductions in the negative effects of road transportation. Shifting cargo to the hyperloop can lead to positive economic and environmental effects, including cost avoidance, emission reduction, and congestion decrease. The hyperloop is projected to have no negative external impacts, marking it as a potential solution for more sustainable and efficient freight transportation.

Impact on Employment

The job creation impact of the was evaluated by approximating the number of jobs created based on investment values from existing industries and projects. Applying an average job creation effect for every €1 billion investment in road construction and rail projects, the hyperloop project could potentially generate between 3,000 to 20,000 jobs, depending on the scenario assessed. This translates to an economic value of between €40M and €280M. The freight transportation shift from trucks to hyperloop could have potential effects on the trucking industry, but these impacts were not calculated or accounted for in this study. Overall, the hyperloop project shows promising potential for job creation and positive economic contribution.

Evaluation of Economic Performance

The economic assessment of the proposed project adhered to the following assumptions. First of all, it used prices at the 2021 level and excluded VAT due to the project's expected public-private partnership delivery model. It applied the concept of shadow prices to reflect the social opportunity cost of goods and services. The model assumed labor costs of 50% for investment and 40% for operating costs, with a shadow wage factor of 0.8.

The economic performance of various project scenarios was evaluated. The Greenports connection is the only single-section scenario that shows a positive economic outcome. The corridor performs well, with an economic value of approximately €500M, which more than doubles when considering the effects of a Dutch hyperloop network and further increases with the expansion of the hyperloop network within Europe.

When considering the residual value of the assets (the remaining value after depreciation) and wider economic benefits such as employment impacts, all scenarios demonstrate a Benefit/Cost (B/C) ratio that is higher than 1 and a corresponding positive economic net present value. In these scenarios, the corridor on its own could generate an economic value of over €1B, which could increase to almost €2B in the long term, considering the network's expansion.

Risk Assessment

The research additionally assesses the proposed corridor's feasibility using a range of analytical methods. Sensitivity analysis highlights how variables such as infrastructure costs, product volume, and pricing significantly affect the project's economic dynamics. The project's resilience is revealed through switching value analysis, indicating it can handle considerable fluctuations in key variables. This resilience is further confirmed by scenario analysis, which demonstrates satisfactory performance under both pessimistic and optimistic conditions. Risk analysis assists in predicting potential hurdles related to planning, administration, land acquisition, design, and construction, among others, while proposing essential mitigation strategies. In conclusion, while the project's economic viability and resilience are clear, its success relies heavily on meticulous planning, collaboration with authorities, and proficient risk management.

Project Realization

A hybrid public-private model is proposed as the most viable delivery model for the project. In this model, the public sector would be responsible for the delivery and ownership of the infrastructure, while private companies would provide transport services. Traditional public or private models have drawbacks, such as inefficiency due to a lack of competition or the need for substantial public subsidies.

The establishment of a hyperloop agency is necessary for implementing the hybrid model. This agency, working in concert with private developers, would be the public counterpart in the project. Its formation should involve multiple ministries to ensure comprehensive oversight.

Public funding is likely to be required for the project to supplement commercial financing. A range of potential sources, including grants and sustainable investment programs, are outlined to help close this funding gap.

Given the innovative nature of Hyperloop technology, the introduction of new legislation specifically tailored to it, dubbed "Law of Hyperloop", is recommended. This legislation could provide a more comprehensive and efficient regulatory framework for the project. The development and implementation of this law would require collaboration with the Dutch government and the European Commission.

Project Realization Schedule

The Cargo-Hyperloop Holland project is realized in accordance with a general transport infrastructure development framework, with a decision-making process being iterated after each preparatory phase. The initial two steps (the concept study and the pre-feasibility study), have been completed so far. As the results of the pre-feasibility assessment are positive and have proven feasibility of the project at this stage, the project will move to the next realization step - the feasibility study, when project partners are defined, and supported by project promoters and stakeholders, undertake a detailed assessment to make the final go/no-go decision about the project implementation. After successfully completing this step, the preparatory process will be finalized by 2024, and the design, engineering and construction will commence. The project will become operational in 2029.

Successfully proving the economic viability of the Cargo-Hyperloop Holland corridor, the next steps will be focused on establishing government leadership for the project, initiating the necessary regulatory adjustments, and conducting further research on the technical aspects of the route, including passenger transport application, and its future role as a part of European hyperloop network.

''The development of the Cargo-Hyperloop Holland corridor will provide a new opportunity for the logistics sector to use a sustainable and fast mode of transportation, first on the regional scale, and then within national and European hyperloop networks.”

Conclusion and Next Steps

In conclusion, the Cargo-Hyperloop Holland corridor offers a sustainable and fast transportation alternative for the logistics sector, providing significant socioeconomic benefits and aligning with strategic European and national objectives. The corridor is expected to attract millions of tonnes of cargo and reduce congestion on Dutch road networks. It will improve competitiveness for regional businesses, reduce carbon emissions, and create thousands of jobs in the Netherlands and Europe. The project will require substantial capital expenditure but has demonstrated high economic value and a positive benefit-to-cost ratio.

The corridor alignment has been independently validated and construction cost estimates confirmed, with further work required to optimize capital expenditures. To maximize the corridor's potential, users will need to adapt their logistics processes, but the economic case remains strong even with reduced demand. A hybrid public-private delivery model is recommended, with the government playing an essential role in project implementation and ensuring optimal pricing.

The full implementation of the Cargo-hyperloop Holland corridor is recommended, but the Greenports section could serve as an economically viable pilot route. This pilot route would demonstrate hyperloop capabilities, build social support, and provide valuable lessons for large-scale deployment. Both the corridor and pilot route infrastructure should be designed to accommodate both cargo and passengers in anticipation of a future European hyperloop network.

Moving forward, the focus will be on establishing government leadership, initiating regulatory adjustments, and conducting further research on the technical aspects of the route, including passenger transport applications and the corridor's role in the European hyperloop network.

Acknowledgements

hyperloopdevelopmentprogram.com

https://hyperloopdevelopmentprogram.com/wp-content/uploads/2021/11/Cargo-Hyperloop-Holland_Full-Report.pdf

File